Diveworks International (DWI) were requested to assist with the installation of a new energy efficient green heat exchange system using sea water. The intake was required to be routed down the quay wall and into the sea. A frame was required for the pipework and filters to be lowered in and out of the water while ensuring they remain protected.

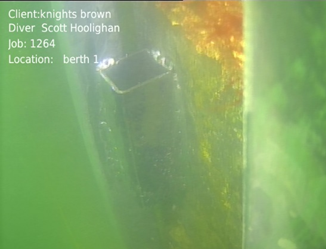

Initial inspection was required which included UT readings to determine the quality of the sheet pile we would be welding to and identify any obstructions that may effect the installation.

The frame was the fabricated based on engineering draings provided by the client, these were hot dipped galvanised and pre-assembled on site.

DWI were instructed to carry out the underwater welding or “wet welding” of the frame to the sheet pile wall. These operations required a full team of trained coded welders to carry out the task.

The project required some pre welding preparation works to be carried, this included the removal of a variety of redundant brackets and plates to clear the area for the frame.

Utilising burning methods the divers removed all obstructions, lowered the frame into position and marked the areas to be welded.

These areas were prepped using a pneumatic powered needle gun and flap grinding disc bringing the areas back to bare metal.

The frame was lowered back in, and tach welded into position, a technique used to temporally secure the structure allowing for the rigging to be removed.

This project required many hours of planning and preparation due to working within an active commercial port, and with several techniques used which are dangerous such as burning and welding.

Wet Welding

Wet welding is a form of hyperbaric welding where the welding isn’t carried out in a dry habitat but with a diver in a wet environment subsurface.

Wet welding relies on the release of gaseous bubbles around an electric arc to shield the weld and prevent any electricity being conducted through the water. This insulating layer of bubbles protects the diver but also obscures the welding area, making it harder to complete the weld correctly. The bubbles can also disturb the welding pool, and the welded joint may cool too quickly due to heat dissipating through the surrounding water. This increases the risk of defects such as cracking. These issues are mitigated by utilising experienced and qualified underwater welders.

Underwater welding uses direct current settings rather than alternating current, as it is safer for the underwater welders to work with.

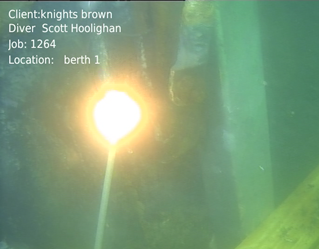

Burning or Arc cutting

Underwater burning and cutting uses underwater exothermic cutting rods with oxygen expelled through the rod and ignited at the tip with 150 amps of direct current from the torch.

The rod will continue to burn with electrical current removed until the flow of oxygen is stopped, or the rod is consumed.

This operation can cut all ferrous and non-ferrous metals thickness from 1 mm to any size it’s burning and melting process with 10000-degree Celsius arc.

Diveworks International (DWI) were requested to assist with the installation of a new energy efficient green heat exchange system using sea water. The intake was required to be routed down the quay wall and into the sea. A frame was required for the pipework and filters to be lowered in and out of the water while ensuring they remain protected.DWI were instructed to carry out the underwater welding or “wet welding” of the frame to the sheet pile wall. These operations required a full team of trained coded welders to carry out the task.

The project required some pre welding preparation works to be carried, this included the removal of a variety of redundant brackets and plates to clear the area for the frame.

Utilising burning methods the divers removed all obstructions, lowered the frame into position and marked the areas to be welded.These areas were prepped using a pneumatic powered needle gun and flap grinding disc bringing the areas back to bare metal. The frame was lowered back in, and tach welded into position, a technique used to temporally secure the structure allowing for the rigging to be removed. The frame was then completely welded into position.

This project required many hours of planning and preparation due to working within an active commercial port, and with several techniques used which are dangerous such as burning and welding.

DWI, having ISO:45001 as well as 9001 and 14001 can cover all areas of risks by following strict procedures leading to a successful completion of the Portsmouth port welding programme.